End of the line for this saw and project, I'm afraid.

With a 925DLX in perfect working condition (my daily driver) and a garage full of too many saws this one is out of luck.

I hope this blog helps folks out in the future and I will still check it for comments and answer any questions people may have.

Click here to go back to the beginning of the blog.

Cheers,

Kent

Sunday, April 4, 2010

Wednesday, March 10, 2010

Got a line on a 7770

Muhahahahaha haaaaaa!

The guy wants $225 for a well cared for 7770 (yuck!). But the motor looks sweet enough for my 925/Frankensaw needs!

Let's wait and see if the price comes down far enough for me to snag it... where I live no one will pay that for the saw in any condition.

The guy wants $225 for a well cared for 7770 (yuck!). But the motor looks sweet enough for my 925/Frankensaw needs!

Let's wait and see if the price comes down far enough for me to snag it... where I live no one will pay that for the saw in any condition.

Friday, February 12, 2010

Time for a 925 hiatus

Big surprise, I know...

With the motor toasted this project is now officially on hold. I will be moving my blogging efforts over to (http://dewaltgwiresto.blogspot.com/). The 925 will stay on the shelf, literally and figuratively, until I find a frame 236 for it.

This could be 3 days or 9 months, it's impossible to say.

I spent a few minutes this morning pulling the motor completely apart to shelve all the parts (rotor, end bells, fan, bearing retainer, screws, tie rods, capacitor, open frame relay, and Klixon). I will see if I can get a few bucks for all the copper in the windings before taking the carcass to the recycle center.

I will be cleaning up the past posts on this blog and adding more pictures as time allows for the sake of history.

With the motor toasted this project is now officially on hold. I will be moving my blogging efforts over to (http://dewaltgwiresto.blogspot.com/). The 925 will stay on the shelf, literally and figuratively, until I find a frame 236 for it.

This could be 3 days or 9 months, it's impossible to say.

I spent a few minutes this morning pulling the motor completely apart to shelve all the parts (rotor, end bells, fan, bearing retainer, screws, tie rods, capacitor, open frame relay, and Klixon). I will see if I can get a few bucks for all the copper in the windings before taking the carcass to the recycle center.

I will be cleaning up the past posts on this blog and adding more pictures as time allows for the sake of history.

Thursday, February 11, 2010

...and yet more motor

I was messing with the motor again this afternoon.

I put the fan back on and ran it for 5 minutes to check out the heat rise. Not too bad, only the rotor got warm. Then I put an 8" blade on it and repeated the test. It seemed to run fine.

Then I turned it off and when I went to turn it back on again I just got a slight movement of the blade and a humming/buzzing motor. Uh, oh. Hmmmm.

The capacitor is new. The relay seems fine (but I can check it). Methinks the start windings might be toast.

I have been on the lookout for another frame 236 anyway since this motor has never given me a very good feeling. Since I have a second 925DLX I might take the 236 off of my hot rod R1350 and put it on this 925 for the restoration, turn the DLX into my daily driver and save the R1350 column for a Frankensaw.

In other news, I am waiting on some goodies for my GWI (http://dewaltgwiresto.blogspot.com/) and I am also planning on having the ways of my 3526 arm re-ground by Original Saw Company (yet another blog). They charge $500 plus $18.52 per bearings if they need to oversize them after grinding the arm. I just need to find a decent way to freight them to Iowa since initial estimates are something like $200 each way. Ouch!

I'll be selling or donating my MBF shortly. It is time to finish up these restorations and pick two saws to keep. I assume it will be the 3526 and the GWI but you never know until they are set up and aligned...

I put the fan back on and ran it for 5 minutes to check out the heat rise. Not too bad, only the rotor got warm. Then I put an 8" blade on it and repeated the test. It seemed to run fine.

Then I turned it off and when I went to turn it back on again I just got a slight movement of the blade and a humming/buzzing motor. Uh, oh. Hmmmm.

The capacitor is new. The relay seems fine (but I can check it). Methinks the start windings might be toast.

I have been on the lookout for another frame 236 anyway since this motor has never given me a very good feeling. Since I have a second 925DLX I might take the 236 off of my hot rod R1350 and put it on this 925 for the restoration, turn the DLX into my daily driver and save the R1350 column for a Frankensaw.

In other news, I am waiting on some goodies for my GWI (http://dewaltgwiresto.blogspot.com/) and I am also planning on having the ways of my 3526 arm re-ground by Original Saw Company (yet another blog). They charge $500 plus $18.52 per bearings if they need to oversize them after grinding the arm. I just need to find a decent way to freight them to Iowa since initial estimates are something like $200 each way. Ouch!

I'll be selling or donating my MBF shortly. It is time to finish up these restorations and pick two saws to keep. I assume it will be the 3526 and the GWI but you never know until they are set up and aligned...

Tuesday, February 9, 2010

It's all about vocabulary

We used words like "polished" and "shiny". OK. This was not exactly what I had expected, LOL! Well, live and learn. This has not been a good winter for my saw restorations.

It just screams "hot rod" which is not a bad thing but I want it to simply state "industrial" in a calm way. I'm curious to see how it will behave inside the column. I can always throw it on the wire wheel and give it a brushed look but, what the heck, maybe I'll like it when I get it all together. I have decided that this particular 925 is going to be pure gloss white so it may just work out fine.

They polished it and then put a coat of copper on, I think, polished that and then hit it with Nickel. Wow. Very reflective. It's tough, too. I tried the wire wheel on the section where the arm goes and the Nickel basically laughed at me.

It just screams "hot rod" which is not a bad thing but I want it to simply state "industrial" in a calm way. I'm curious to see how it will behave inside the column. I can always throw it on the wire wheel and give it a brushed look but, what the heck, maybe I'll like it when I get it all together. I have decided that this particular 925 is going to be pure gloss white so it may just work out fine.

They polished it and then put a coat of copper on, I think, polished that and then hit it with Nickel. Wow. Very reflective. It's tough, too. I tried the wire wheel on the section where the arm goes and the Nickel basically laughed at me.

Friday, January 22, 2010

The Column - Off to the shop!

OK, back at it!

I took the column down to a "chrome shop" today. Superior Chrome in San Jose, CA. they're big into custom cars and such - show quality chrome.

They will "strip" (bead blast) and hand "polish" (hellifiknow) the column and then coat it with nickel. This costs $120.00. It may sound like a lot but if you've ever stood and bent over a wire wheel with a 25 pound chunk of steel for 1/2 hour you don't know what pain is. It hurts the back, arms, and eyes. No, thanks!

The last ghetto shop I used did not "polish" before electroless nickel plating my MBF column and it came back pretty darned nice ($85.00). I predict this shop will produce a killer column.

I'll post pictures as soon as it comes back (~2 weeks).

I took the column down to a "chrome shop" today. Superior Chrome in San Jose, CA. they're big into custom cars and such - show quality chrome.

They will "strip" (bead blast) and hand "polish" (hellifiknow) the column and then coat it with nickel. This costs $120.00. It may sound like a lot but if you've ever stood and bent over a wire wheel with a 25 pound chunk of steel for 1/2 hour you don't know what pain is. It hurts the back, arms, and eyes. No, thanks!

The last ghetto shop I used did not "polish" before electroless nickel plating my MBF column and it came back pretty darned nice ($85.00). I predict this shop will produce a killer column.

I'll post pictures as soon as it comes back (~2 weeks).

Thursday, January 14, 2010

Still not quite there with the GWI

I loath drive screws. I really do.

Unfortunately the 925 will be put off for another week while I sort out the GWI.

I also received the last of the parts needed to begin work on the long awaited modern DC saw brake. More on that later.

Unfortunately the 925 will be put off for another week while I sort out the GWI.

I also received the last of the parts needed to begin work on the long awaited modern DC saw brake. More on that later.

Tuesday, January 12, 2010

What's taking so long?

I haven't been active with this saw because I am preparing to get my GWI back from the paint shop and need to make sure I am ready to put it together when it comes back.

I just need to get the column ready to be polished and then I'll get back to work on this 925 and start posting regularly again.

I just need to get the column ready to be polished and then I'll get back to work on this 925 and start posting regularly again.

Friday, January 8, 2010

Centrifugal Brake

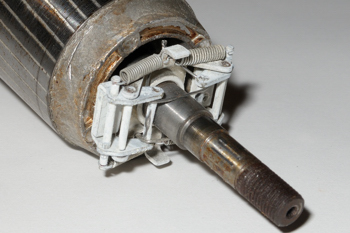

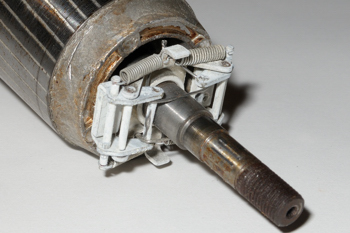

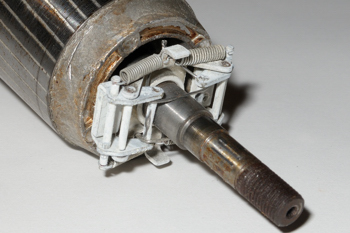

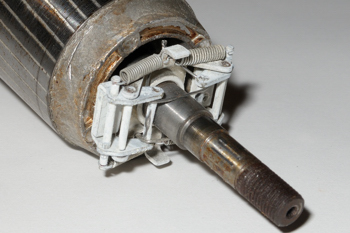

So I pulled apart the motor and took a close look at this thing.

It doesn't appear to ever have worked, basically. When the motor is not running it should scrape lightly against the housing next to the rear motor bearing. When the rotor is spinning, centrifugal force should pull the two arms scraping the housing away from it by what looks like 3-4mm. On mine the arms can't even reach the housing.

It looks like the previous owner may have wired it open for some reason.

In this picture the surfaces are all covered with some white rust/residue which should be worn away where the arms scrape the housing.

While I was in there I cut out a bit more of the insulating material mentioned here. Now the motor does not make the "tiff, tiff, tiff" sound although when I run the motor (albeit with the rear fan removed) the rotor still warms up for some reason.

My experience with this sort of thing is very limited. On my GWI motor, on which I spent a lot of time getting it perfect, I found that if there isn't enough forward pressure on the front bearing via the rotor that it will heat up. I solved that on the GWI by adjusting the rear bearing by pulling it off of the shoulder slightly so that there was more pressure on the front bearing. It worked like a champ although many folks felt this was the wrong thing to do (bearings should always be pressed onto the shoulder, etc..) Personally, I go with what works. The motor was quiet, powerful, no oscillations, and didn't heat up. Good enough for me.

Given that the rear bearing on the frame 235 "floats" so I don't think I have the same option here. Any suggestions?

It doesn't appear to ever have worked, basically. When the motor is not running it should scrape lightly against the housing next to the rear motor bearing. When the rotor is spinning, centrifugal force should pull the two arms scraping the housing away from it by what looks like 3-4mm. On mine the arms can't even reach the housing.

It looks like the previous owner may have wired it open for some reason.

In this picture the surfaces are all covered with some white rust/residue which should be worn away where the arms scrape the housing.

While I was in there I cut out a bit more of the insulating material mentioned here. Now the motor does not make the "tiff, tiff, tiff" sound although when I run the motor (albeit with the rear fan removed) the rotor still warms up for some reason.

My experience with this sort of thing is very limited. On my GWI motor, on which I spent a lot of time getting it perfect, I found that if there isn't enough forward pressure on the front bearing via the rotor that it will heat up. I solved that on the GWI by adjusting the rear bearing by pulling it off of the shoulder slightly so that there was more pressure on the front bearing. It worked like a champ although many folks felt this was the wrong thing to do (bearings should always be pressed onto the shoulder, etc..) Personally, I go with what works. The motor was quiet, powerful, no oscillations, and didn't heat up. Good enough for me.

Given that the rear bearing on the frame 235 "floats" so I don't think I have the same option here. Any suggestions?

Wednesday, January 6, 2010

Just a bit more motor

I picked up a 925DLX and after running it concluded that the centrifugal brake on my 925 is not functioning. I'm going to pull apart the motor and remove it for my next post. I'll post a lot of pictures.

Here you can see it is stuck open (I think):

I've been working on a design for an electric brake anyway and this saw will be the test bed for my prototype.

Just to be clear, it will not be "my design" but rather a hybrid of ideas that have been freely offered to me from sources such as J Scott McCauley and others, from the various forums and other individuals that might have ways of solving this problem with modern, easy to obtain parts. These folks have forgotten way more than I will ever know about basic EE concepts.

Any design that I actually get working will be freely available to anyone, with sources sited, who has an internet connection and can read. I will include the part numbers and where you can actually buy the parts online (unique nowadays, I know) although this is becoming a daunting task as I work (full time) for a living and building saws is secondary to me earning a living and paying the bills.

As a side note, if you follow this blog please feel free to sign up for a free google gmail account and add as much as you want to the blog. I welcome flames, good info, whatever. It's all good.

There is no money in vintage RAS restoration. Period.

Here you can see it is stuck open (I think):

I've been working on a design for an electric brake anyway and this saw will be the test bed for my prototype.

Just to be clear, it will not be "my design" but rather a hybrid of ideas that have been freely offered to me from sources such as J Scott McCauley and others, from the various forums and other individuals that might have ways of solving this problem with modern, easy to obtain parts. These folks have forgotten way more than I will ever know about basic EE concepts.

Any design that I actually get working will be freely available to anyone, with sources sited, who has an internet connection and can read. I will include the part numbers and where you can actually buy the parts online (unique nowadays, I know) although this is becoming a daunting task as I work (full time) for a living and building saws is secondary to me earning a living and paying the bills.

As a side note, if you follow this blog please feel free to sign up for a free google gmail account and add as much as you want to the blog. I welcome flames, good info, whatever. It's all good.

There is no money in vintage RAS restoration. Period.

Tuesday, January 5, 2010

OT - Payback is a ... well, you know

I got a lead on a drill press today from a friend. Here's a standard (incredibly poor) image of it:

$100.00... for a Powermatic 15XX? Uh, YEAH!

I jumped in the SUV and bailed over there (Stanford University) post haste.

Exactly one hour after seeing this bad boy on CL I pulled up and realized I was about 15 minutes too late. Drat!

This place is only open from 12-4 on Tuesdays so I felt my chances were good. I guess not.

It was in waaaaay better condition than the image indicates. Single phase, great condition. Bummer.

I think this is a Karma thing for me getting jaded about hunting for these machines and capping on folks posting stuff for sale.

$100.00... for a Powermatic 15XX? Uh, YEAH!

I jumped in the SUV and bailed over there (Stanford University) post haste.

Exactly one hour after seeing this bad boy on CL I pulled up and realized I was about 15 minutes too late. Drat!

This place is only open from 12-4 on Tuesdays so I felt my chances were good. I guess not.

It was in waaaaay better condition than the image indicates. Single phase, great condition. Bummer.

I think this is a Karma thing for me getting jaded about hunting for these machines and capping on folks posting stuff for sale.

Friday, January 1, 2010

The Obligatory Plug for Mr. Sawdust

This is just one of those things. Get this book:

http://www.mrsawdust.com/

It is THE authority on the history, setup, use, and restoration of DeWalt Radial Arm Saws. It is also one heck of a primer on woodworking using a RAS. At $30.00 it's basically like stealing. The tips and tricks sprinkled throughout are worth $100 all by themselves.

Seriously, get this book.

http://www.mrsawdust.com/

It is THE authority on the history, setup, use, and restoration of DeWalt Radial Arm Saws. It is also one heck of a primer on woodworking using a RAS. At $30.00 it's basically like stealing. The tips and tricks sprinkled throughout are worth $100 all by themselves.

Seriously, get this book.

Subscribe to:

Posts (Atom)